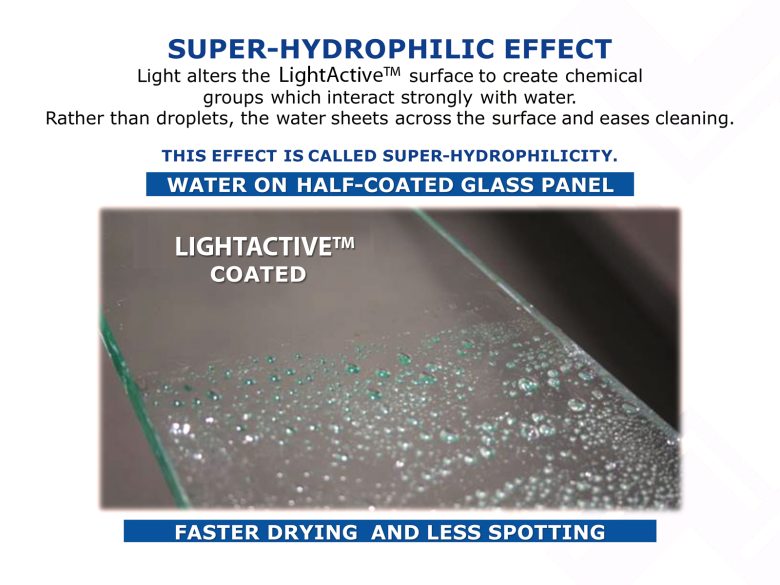

A remarkable feature of photocatalysts is light induced ‘water-shedding’ or super hydrophilicity. In the presence of light, the photocatalyst transparent film of LightActive™ actually acts as a ‘wetting agent’ that helps water sheet off, instead of typical beading which leaves spots. The coating forms a very thin water film which easily runs off, taking dirt, oils and contaminants with it.

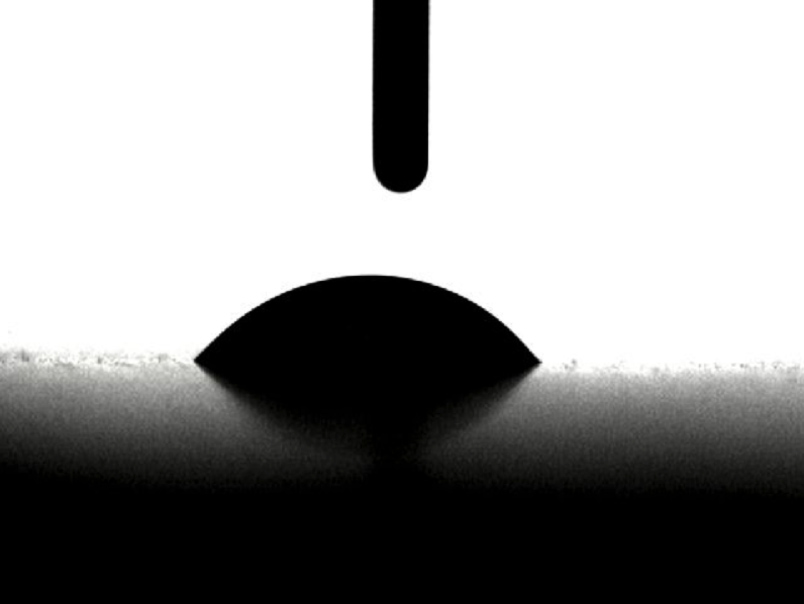

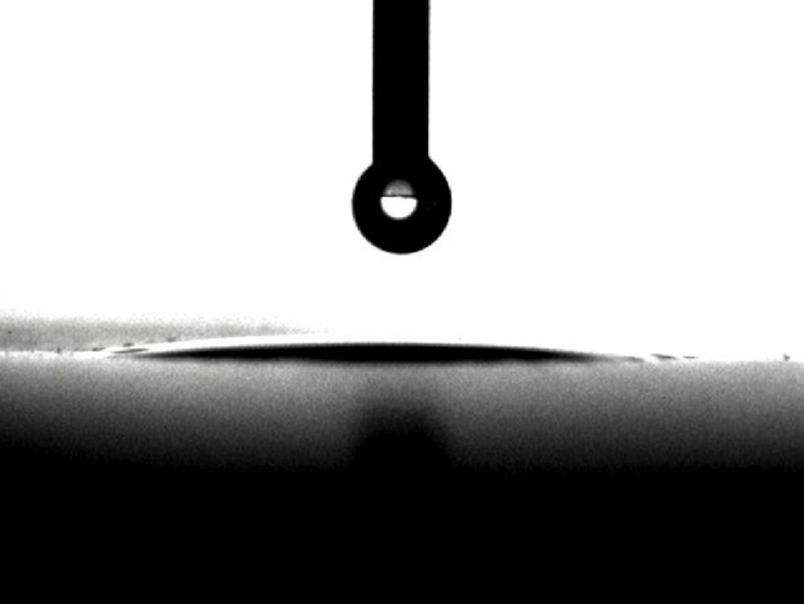

The assumed mechanism of super hydrophilicity is novel, yet simple: the light activated coating reduces the contact angle of water on its surface by attracting the oxygen in water. The photocatalyst coating does not repel water so water cannot exist in the shape of a drop. Instead, water spreads flatly on the surface and sheets off with the LightActive™ coating acting as a surfactant.

Benefits of hydrophilicity include less spotting, ease of dirt release and oil removal (the applied LightActive™ coating is oleophobic), reduction in cleaning costs and faster evaporation. In conjunction with LightActive™’s photo-oxidation of organics, all contaminants are also more easily washed off. Oils, including most exhaust products, can easily be removed. A simple rainfall or water wash is effective because the treated surface has a greater affinity for the water than the oil.

Importantly, LightActive™ on a surface also increases heat transfer. For example, on metals, such as evaporators in air conditioning systems, the hydrophilic coating will exhibit superior heat transfer performance by inducing film flow (and evaporation) versus the larger sessile droplets on an untreated surface. In general, the thin film provides greater heat transfer than the comparatively large drops, promoting more of the desired evaporative effect. Additionally, dynamic simulations of heat flow show significant heat transfer enhancement due to the increased surface area of a nanostructured surface.

For general applications of LightActive™, the combination of organic decomposition and the water-release effect of contaminants add to the self-cleaning aspect of our coating. On exteriors, building surfaces shed dirt and grime more easily, providing a more attractive appearance, requiring lower maintenance. For interior applications where the reduction of organic challenges are available with ordinary lighting, LightActive™ treated surfaces can be easily cleaned with water, reducing the frequency, hazards and expense of harsh cleansers.

LightActive™ self-assembling coatings have been engineered to provide increased hydrophilic effects even in the dark on some substrates. With the addition of light energy, the coatings become super hydrophilic, creating near zero contact angles for maximum self-cleaning. Light or dark, LightActive™ is working 24 hours a day to promote cleaner, more efficient surfaces.