LightActive Intelligent Surfaces™ are on the job 24/7/365 to continuously reduce contamination on the treated surface. Always ready to work, the Intelligent Surface™ is a durable, virtually invisible, self-cleaning surface that photo-oxidizes surface organics and breaks down VOCs and other noxious pollutants and odors in the air using only the energy of light.

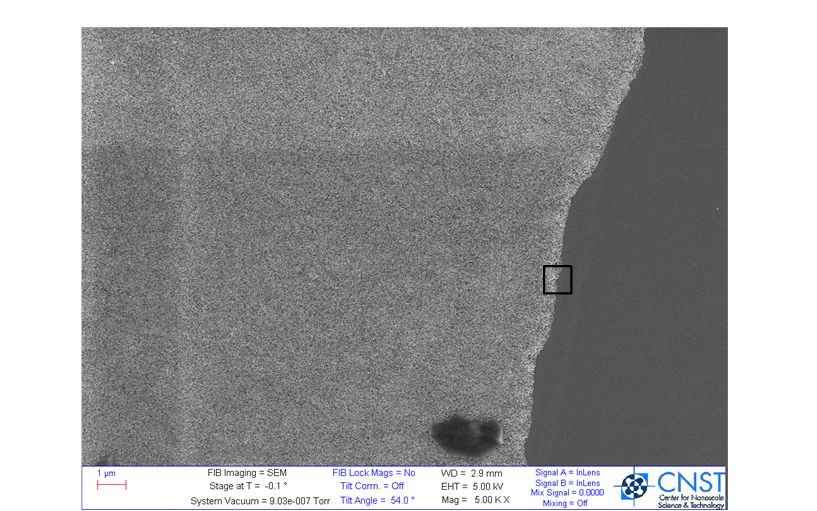

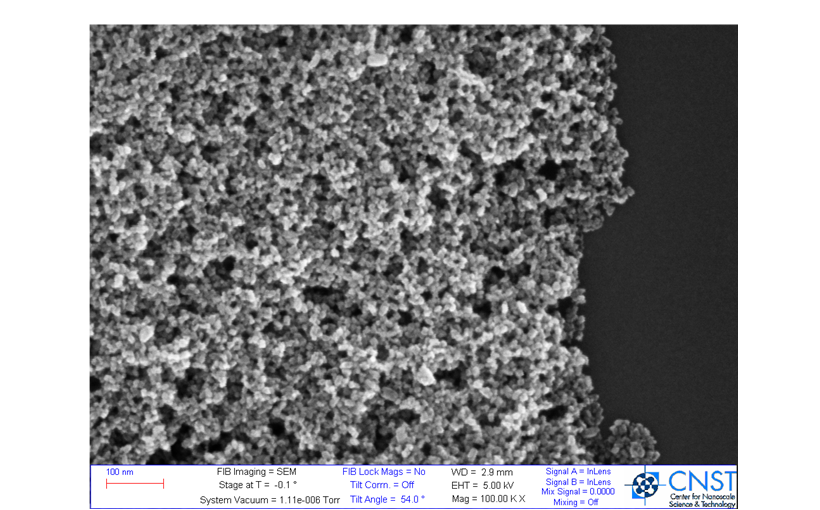

Upon application, LightActive™ self-assembles to create an extremely high surface area, homogeneous, and essentially transparent thin film anatase coating that is highly responsive to illumination from both sunlight and/or typical indoor lighting.

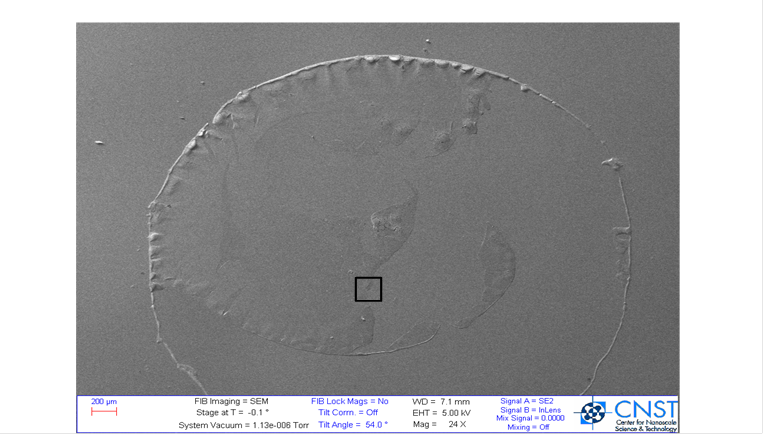

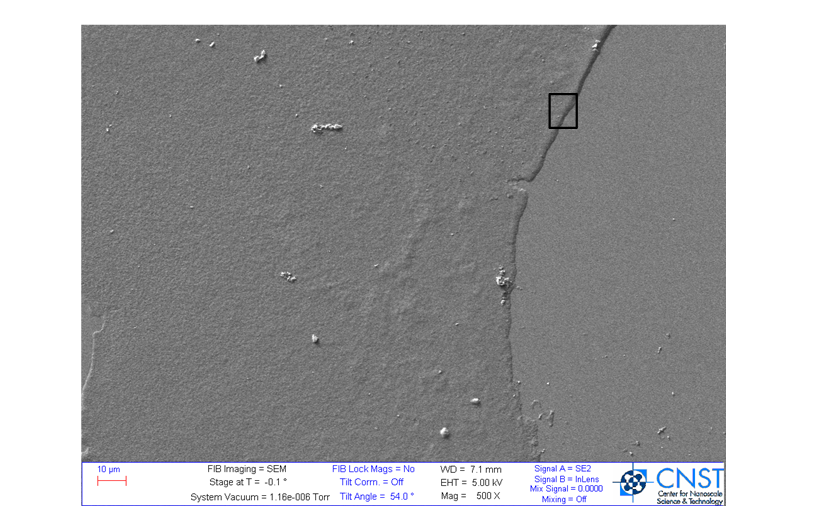

Images of LightActive™ by Scanning Electron Microscope (SEM), Center for Nanoscale Science and Technology (CNST), National Institute of Standards and Technology (NIST), U.S. Department of Commerce. LightActive™ 50 fold reduction dilution for observable edge definition.

The Intelligent Surface™ is essentially transparent because the self-assembled film of anatase (one of the three crystal shapes of titanium dioxide) is typically thinner than half a micrometer. Despite being mostly transparent in visible light, LightActive™ efficiently blocks Ultraviolet Light (UV), similar to the titanium dioxide (TiO₂) that is the ingredient in the safest transparent mineral sunscreens. This adds protection to surfaces that are vulnerable to UV.

LightActive™ is carefully engineered to maximize its functionality as a photocatalyst surface while being nearly invisible and applicable to almost any surface, existing or new. Traditional TiO₂ photocatalysts react only to Ultraviolet (UV) light, which is only 3% of available solar energy. However, the LightActive™ Intelligent Surface™ is also a strongly active photocatalytic oxidizer under visible light, which represents over 44% of the Sun’s energy. Patented LightActive™ is much more effective than other photocatalysts because it gathers more total light energy in outdoor conditions. Additionally, the distinctive ability of LightActive™ to be a high performance photocatalyst using only visible light brings this powerful light-powered chemistry indoors, where air quality and surface contamination are a greater challenge to human health.

The Intelligent Surface™ absorbs energetic photons to create free electrons and positively charged holes in the crystal structure. These entities migrate within the crystal to the surface where they interact with water molecules to create highly chemically reactive hydroxyl and superoxide free radicals, a process termed photocatalysis. This continual use of light energy does not consume or deplete the LightActive™ catalyst, providing a long Intelligent Surface™ service life.

The reaction rate of any photocatalyst is affected by crystal composition, illumination characteristics, and the available surface area. LightActive™ is designed to use all these performance parameters for maximum real world effectiveness. Bulk TiO₂, such as incorporated into paints, plastics and paper, provides very little oxidizing effect, even under UV light. In contrast, LightActive™ uses advanced materials science to optimize crystal structure and reduce crystal size, affording a massive increase in surface area per unit of mass compared to more familiar titanium dioxide dimensions. The multiple improvements embodied in LightActive™ result in superior photocatalytic activity to provide an efficient Intelligent Surface™. The reactive oxygen species (ROS) generated from our Intelligent Surfaces™ can oxidize any organic material in its diffusion range, affording a broad range of benefits in the environment.

To maximize the durability and bonding of the applied Intelligent Surface™, LightActive™ utilizes to its advantage the same physics forces that drastically reduces effectiveness of other, conventional photocatalysts: agglomeration. High surface area to mass particles want to stick to each other (agglomerate) and form ever larger solids, decreasing surface area. LightActive™ is carefully manufactured to form a colloidal suspension in water in order to keep the crystalline particles separate until LightActive™ reaches the target surface. After application the water then evaporates, allowing the self-assembly of the crystalline Intelligent Surface™ to virtually any surface. The physico-chemical characteristics of LightActive™ result in strong binding interactions among the crystals and the chosen target surface due to ionic and van der Waals interactions. Because of the incredibly large surface area to mass ratios of the LightActive™ coating, these atomic surface interactions tend to dominate over forces that might otherwise displace interacting materials (e.g. shearing forces). The Intelligent Surface™ becomes strongly bonded and forms a mesoporous, high performance, transparent photocatalytic surface. Like all coatings, abrasion will eventually degrade the Intelligent Surface and renewal application is simple

The combination of maximum light energy response (both UV AND visible), maximum surface area (on the target surface, not just in the lab), and durability (on any surface, new or existing) makes the LightActive™ Intelligent Surface™ the most advanced self-cleaning coating in the world.