LightActive™ is a composite matrix material containing only chemical elements (titanium, silicon, zinc, and oxygen) which uses the energy of visible and UV light to split molecules of water vapor in ordinary air into compounds called reactive oxygen species (ROS) that react with and degrade organic molecules. This well-known process of transforming light and water into ROS is called photocatalysis.

The LightActive Intelligent Surface™ is composed of mineral oxides, and it does not get used up in the process of transforming light energy and water into ROS. Also, ROS do not penetrate skin, do not leach, and exist only long enough to act on organic compounds that come into contact with the surface.

Photocatalytic water-splitting has been known for many years. Titanium dioxide-based coatings are manufactured onto many types of commercial window glass for its self-cleaning properties. However, LightActive™ contains innovations that allow it to work using visible light rather than just the UV light required by other photocatalytic materials. This use of visible light energy allows LightActive™ to work indoors, and also makes it more effective than conventional photocatalysts outdoors because it utilizes both UV and visible light energy. Importantly, LightActive™ is engineered so it can be applied to most existing surfaces, both indoors and out.

What It Can Do

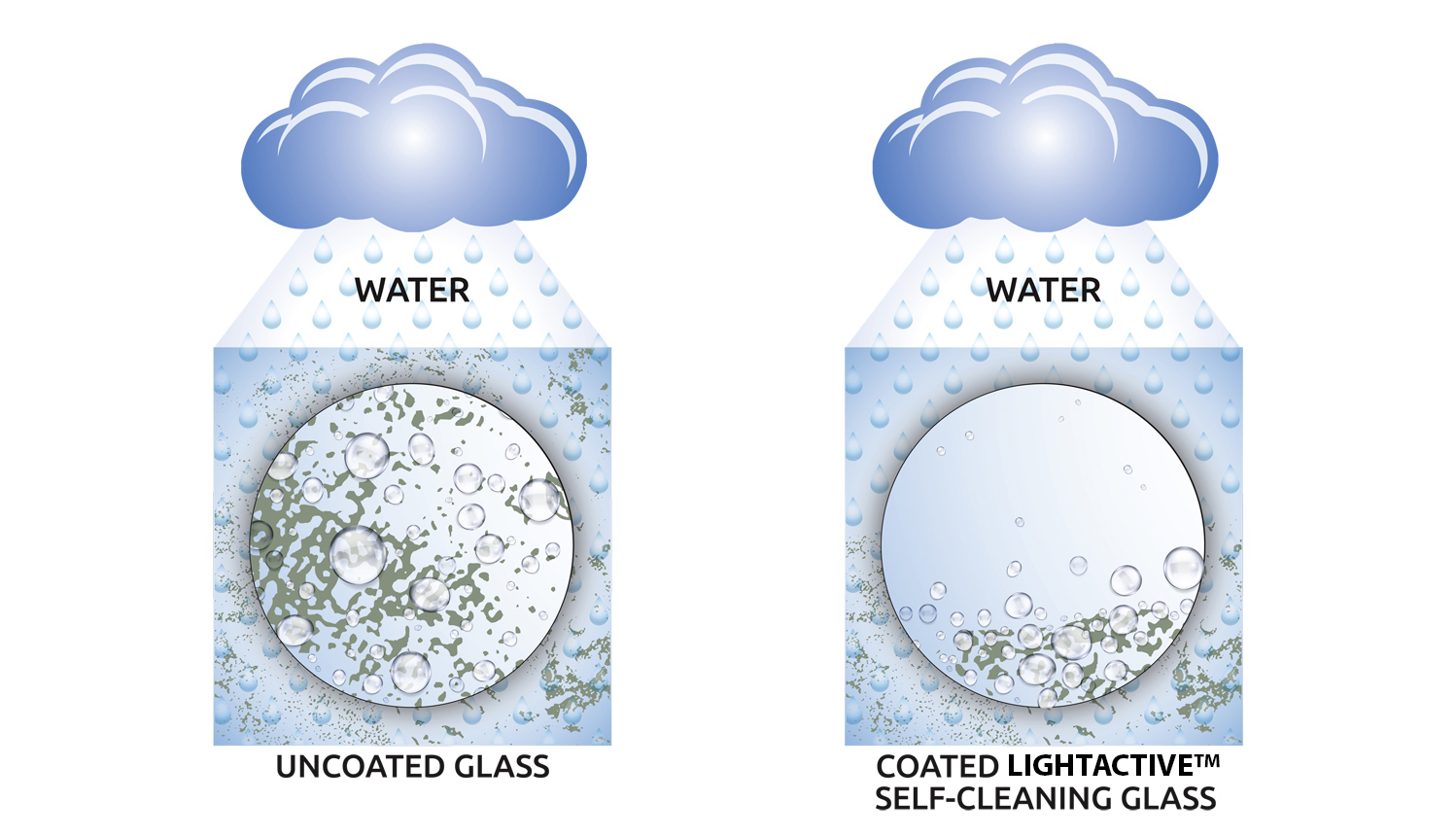

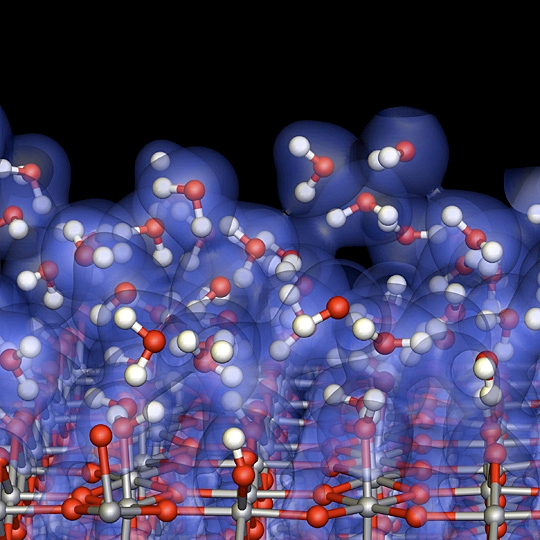

LightActive™ surfaces interact with their environment to enhance cleanliness. These Intelligent Surfaces™ reduce organic surface contamination and will reduce many air pollutants as well. While continuously destroying contaminants, an illuminated LightActive™ surface also interacts with and responds to water and sheets it off, releasing both organic and inorganic materials on its surface. The inherent nature of the film is also a highly effective UV absorber, protecting surfaces from degradation. As a thin film oxide coating, additional corrosion protection is given to many metals, lengthening service life.

How Is LightActive™ Different?

A LightActive™ coating is composed only of carefully prepared but common mineral oxide crystals that exhibit the remarkable property of photocatalysis. Not only is the Smart Film™ durable, but the photocatalytic activity is continuous; it requires no require human intervention beyond maintaining ordinary illumination: special lamps are not needed.

The distinctive mechanism underpinning the photocatalytic effect is well understood, very general, surface-localized, and non-contaminating. Also, LightActive™ is engineered so that application to the target surface maximizes Real World performance.

Mechanism of Organic and VOC Reduction

Hydrophilic Self Cleaning